The Problem

At Chobani’s Twin Falls food processing facility, many different raw ingredients are used to produce the company’s dairy products including sugar, tapioca, fruit and flavors. Dry powders need to be weighed, poured and mixed throughout yogurt production which releases fine airborne dust particles, impacting indoor air quality.

All of the food powders used in production are combustible dusts and have a KST value (Dust Explosivity) which requires a dust collection system to control combustible dust clouds to comply with NFPA guidelines.

Chobani reached out to Diversitech to supply a wet dust collection system to safely capture and collect combustible dust from various food processing operations to protect workers and their production facility. This collector had to be portable so Chobani could easily transport the machine around their facility, and had to protect their workers from the following health and safety risks:

- Flash fire

- Combustible dust explosion

- Bacterial contamination

- Asthma

- Reduced lung function

- Nasal, eye and skin irritation

The Solution

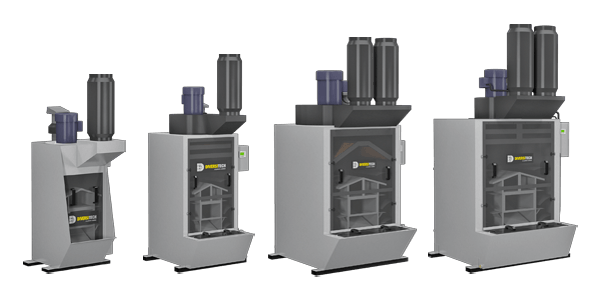

Following an analysis of Chobani’s specific requirements, Diversitech proposed a portable and fully stainless steel Typhoon WX-3000 Wet Dust Collector which could meet FDA washdown requirements to maintain cleanliness in a food production facility.

The portable wet dust collector came outfitted with a portable caster base, water refill tank, stainless steel explosion-proof motor and wiring, stainless steel NEMA 4X PLC control panel, and a stainless steel HEPA after filter and frame to ensure even sub-micron particles were removed from the airstream. This custom-engineered product was designed to meet all of Chobani’s specific concerns and to meet all applicable NFPA, OSHA clean air and FDA regulations.