One of the most common applications in metal fabrication, cutting involves the severing of sheets of metal into smaller sections or parts.  Whether cutting freshly made steel or preshaped metal, cutters employ a wide range of equipment including bladed saws, power scissors as well as laser and plasma torches.

Whether cutting freshly made steel or preshaped metal, cutters employ a wide range of equipment including bladed saws, power scissors as well as laser and plasma torches.

Frequently used in fab shops, plasma cutting creates an electrical arc with inert gas blown at high speeds. Some cutters use hand-held plasma torches to gouge holes or remove parts. But to get really fine, exact cuts, many fab shops opt for CNC plasma machines.

Using an automated computer numerical control (CNC), these machines make cuts with a straight barrel torch and a jet of hot plasma. Because of the extremely high temperatures involved, CNC plasma cutting produces microscopic particulate that can be very hazardous to worker health. Smaller particles are easily absorbed into the lungs of metal workers and as a result pose a more dangerous threat to their health. When these contaminants contain toxic metals as they do in fab shops, the health consequences are dire.

Laser cutting on the other hand, uses a high-powered laser beam to cut metal into various shapes or designs. Usually used on thinner sheets of metals, laser cutting may also involve a gas jet to disperse molten metal. While laser cutting creates less contamination and waste compared to other applications, it still produces highly toxic metals fumes that pose an immediate threat to worker health.

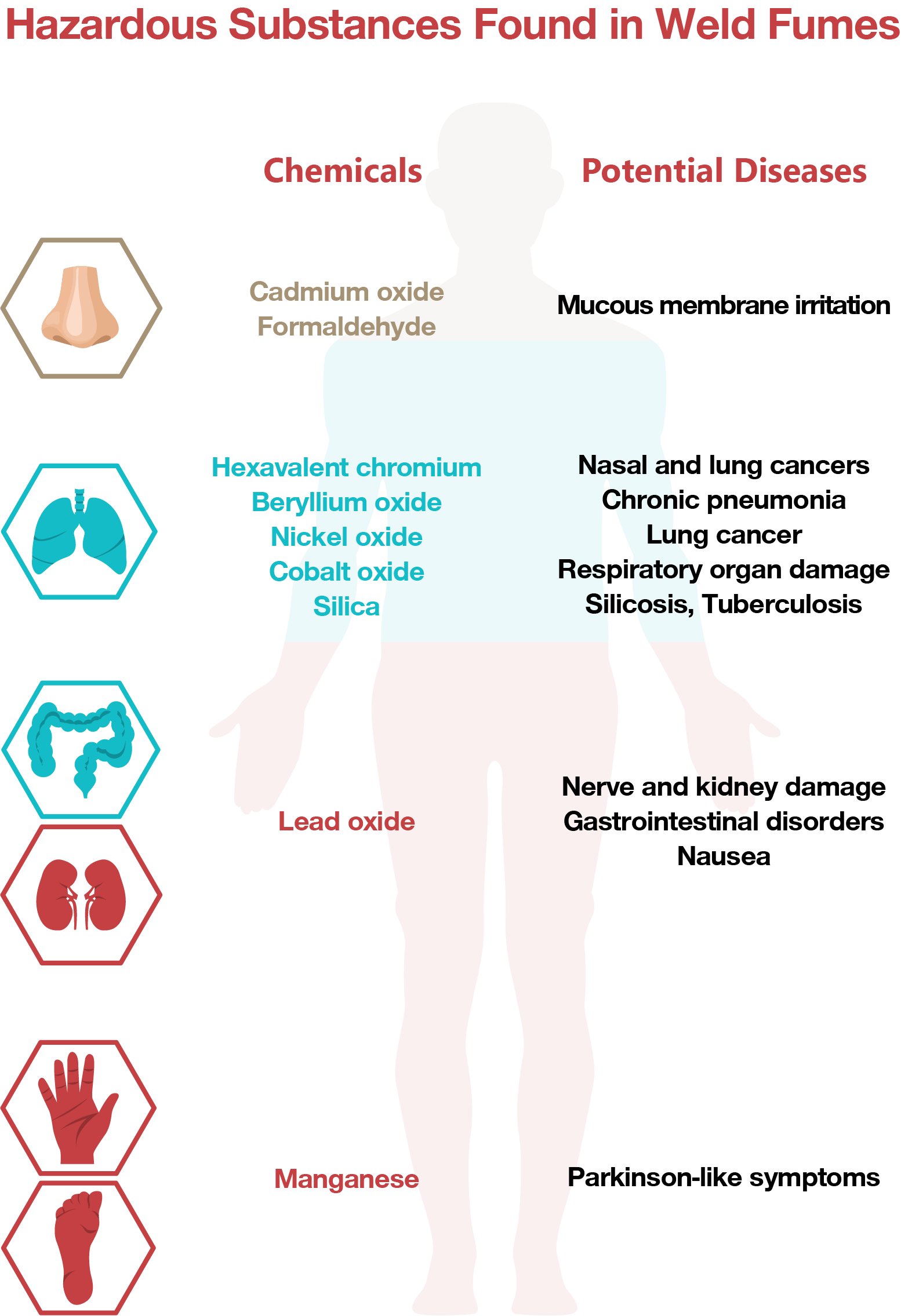

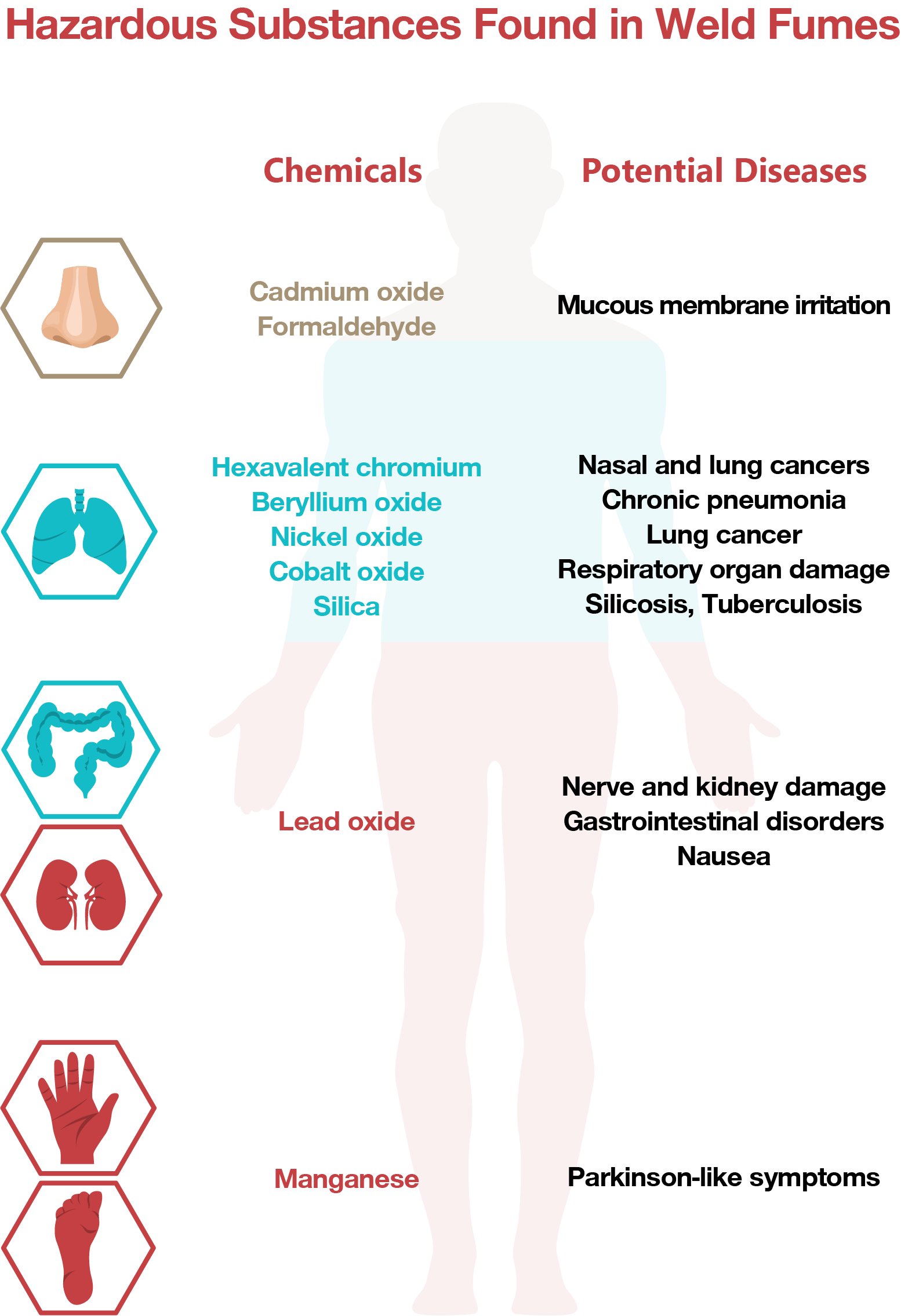

Another common fab shop application, welding joins together two separate metal parts using heat from an electric arc, or some other tool. Like plasma and laser cutting, welding produces a number of toxins that can potentially harm worker health when inhaled.

Hexavalent chromium or Cr6, is a byproduct of cutting and welding stainless or galvanized steel. A highly toxic carcinogen, workers exposed to Cr6 run the risk of developing a number of health conditions. Along with lung and nasal cancers, hexavalent chromium can cause:

- Skin and respiratory irritation

- Liver and kidney damage

- Nasal perforation and sores

- Birth defects

Other toxic materials that pose serious health risks to welders and cutters include iron, copper, zinc, nickel, manganese, aluminum, tin, beryllium, cadmium, lead and titanium. The smoke and fumes from these metals irritate the nose, throat and eyes. They can also potentially damage the brain, nervous system, lung and kidneys. Exposure to manganese can lead to managanism, a nervous system disorder with symptoms that mimic Parkinson’s. Some metals, like nickel, are carcinogenic and others like cadmium can be fatal.

Without proper protections in place, welders and cutters who work with galvanized steel also put themselves at risk of developing metal fume fever. Usually lasting no more than a day, this illness comes with flu-like symptoms such as fever, weakness, fatigue, chills, aches, nausea and chills.

The zinc released when welding or cutting galvanized steel poses other health risks as well. Inhaled in large quantities over a short period of time, zinc can be fatal. Other conditions caused by zinc fumes include:

- Skin, eyes, lungs and mucus membrane irritation

- Dermatitis, rashes and chemical burns

- Difficulty breathing

- Chest pain

- Tightness

Many of the dusts created from plasma and laser cutting are also combustible and present a serious threat of fire and explosion.

OSHA has a number of regulations in place to protect the health and welfare of welders and cutters. Besides personal protective equipment, OSHA recommends engineered controls that collect dust, smoke and fume at source. Diversitech offers a range of extractions arms, portable fume extractors and downdraft tables to keep you OSHA compliant. These systems collect toxins before they have a chance to contaminate indoor shop air and remain the trusted choice of North America’s largest manufacturers. For the safe capture of combustibles, one of Diversitech’s wet downdraft tables is recommended.

Whether cutting freshly made steel or preshaped metal, cutters employ a wide range of equipment including bladed saws, power scissors as well as laser and plasma torches.

Whether cutting freshly made steel or preshaped metal, cutters employ a wide range of equipment including bladed saws, power scissors as well as laser and plasma torches. that pose a number of health risks. Knowing the kind of metal being ground, sanded or deburred is crucial in understanding how to best protect workers.

that pose a number of health risks. Knowing the kind of metal being ground, sanded or deburred is crucial in understanding how to best protect workers. It’s for this reason many fab shops also incorporate these applications into their services.

It’s for this reason many fab shops also incorporate these applications into their services.