Manual and Robotic Welding

The manufacture of heavy equipment in the oil & gas industry requires the manual or robotic welding of parts. An application that connects two separate metal parts using heat from an electric arc, welding is used to construct pipelines, beams, tools, equipment and machines in the oil & gas sector.

The fumes created by welding processes contain toxins that pose serious health risks to workers if inhaled. The type of toxin and the resulting illness depends on the type of welding as well as the material used. Common toxic metals found in welding fume include manganese, nickel, lead, chromium, beryllium and aluminum. Each metal poses its own unique health risk to workers. Lead, for example, can damage the nervous system, kidneys, digestive system and the brain. Fumes that contain nickel pose an increased cancer risk and can irritate the eyes, nose and throat.

Used in the fabrication of storage tanks, valves and other components, stainless and galvanized steel are common metals used in the oil and gas industry. The welding of stainless steel is especially dangerous as it exposes workers to the carcinogen hexavalent chromium (Cr6). Besides putting welders at risk for developing lung and nasal cancer, Cr6 can cause eye and respiratory irritation, birth defects, ulcerations, lesions, pulmonary congestion, edema and liver and kidney failure.

The particle size of the contaminants present is also a factor in determining how dangerous the weld fumes will be. The smaller the particles, the more easily they penetrate the lungs and the more serious the threat to worker health.

For pipeline fabrication, Metal Inert Gas (MIG) Welding is often used. Despite creating lower emissions, MIG welding still produces highly toxic fumes. Like other forms of welding, MIG welding puts workers at risk of developing a number of conditions including cancer. Other health risks associated with welding include:

- Metal fume fever

- Manganism

- Lung, bowel, intestine and liver cancers

- Neurological diseases

- Pneumonia

- Asthma

- Skin diseases

- Allergies

- Fertility problems

- Emphysema

- Respiratory damage

Because weld fumes remain a serious threat to employee health, the Occupational Safety and Health Administration (OSHA) has set guidelines for protecting workers in the industry. Failure to follow the permissible exposure limits (PELs) for airborne contaminants set by OSHA can result in serious legal and financial consequences for businesses.

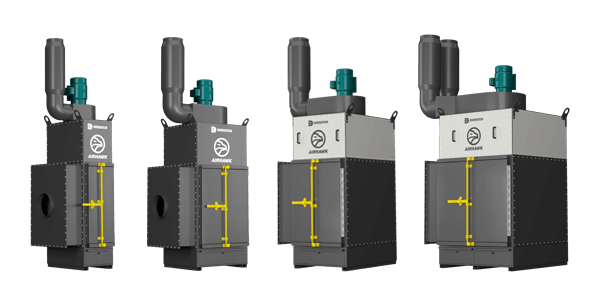

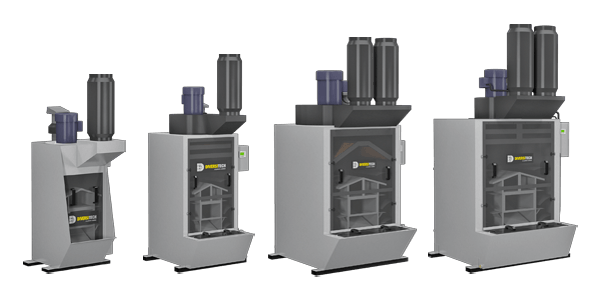

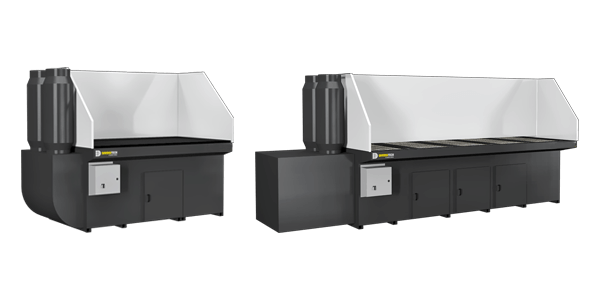

To help keep companies in the oil & gas sector OSHA compliant, Diversitech provides a number of ventilation options. Capture-at-source remains the best for collecting toxic weld fumes and protecting worker health. The trusted choice of North America’s largest manufacturers, Diversitech offers various extractions arms, portable fume extractors and downdraft tables that collect harmful toxins before they have a chance to contaminate indoor shop air. For robotic welding, we recommend one of our robotic ventilation hoods or robotic weld cell collectors.