Commonly used in the construction industry, woodworking entails the many processes involved with the fabrication of wooden structures.  The planing, sawing, routing, milling, drilling and sanding of wood are all woodworking applications. Each one of these processes create large amounts of dusts that can harm worker health.

The planing, sawing, routing, milling, drilling and sanding of wood are all woodworking applications. Each one of these processes create large amounts of dusts that can harm worker health.

Potentially causing nasal, paranasal and nasopharynx cancers, the International Agency for Research on Cancer (IARC) has classified wood dust as a carcinogen. But it’s not just cancer that workers need to worry about. Wood dust exposure can lead to a wide range of concerning conditions.

The type of illness depends directly on the species of wood. Cedar dust, for example, can lead to asthma, allergic contact dermatitis, rhinitis, decreased lung function, or eye irritation and conjunctivitis. Exposure to oak dust, on the other hand, can cause nasal cancer.

Other conditions that may result from wood dust exposure include:

- Shortness of breath

- Dry, sore throat

- Conjunctivitis

- Occupational asthma

- Chronic bronchitis

- Hypersensitivity pneumonitis (inflammation of the airways and air sac walls)

Chemicals from the wood dust enter through the worker’s skin, lungs and digestive system. Once absorbed, these wood chemicals can cause a number of symptoms such as:

- Giddiness

- Headaches

- Weight loss

- Breathlessness

- Cramps

- Irregular heartbeat

But it’s not just the wood itself that can lead to illness. Wood dust often contains mold, fungi and bacteria which can cause hypersensitivity pneumonitis, Maple Bark Stripper’s disease or Wood-Pulp Worker’s disease.

Given the right conditions, wood dust is also combustible. If allowed to accumulate in duct work and on factory surfaces, fire and explosion can result, putting workers’ lives and welfare as well as company property at risk.

Both the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have guidelines in place to protect worker health and safety. Installing local exhaust ventilation systems is the best method to capture and remove wood dust at source.

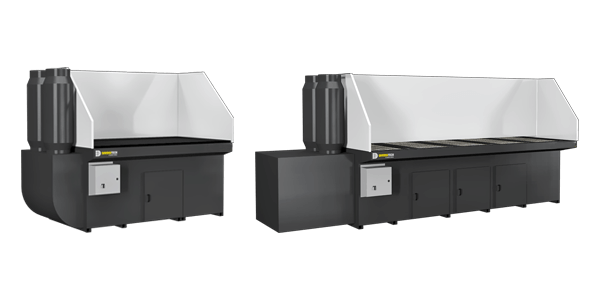

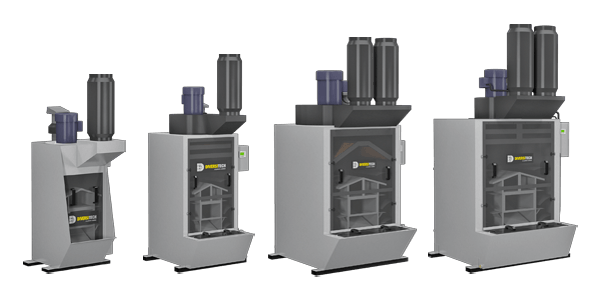

Helping keep businesses in the woodworking and construction industries NFPA and OSHA compliant, Diversitech offers a number of combustible dust filtration options. Our wet dust collectors and wet downdraft tables safely capture flammable dusts and help protect workers from wood dust related illnesses.

The planing, sawing, routing, milling, drilling and sanding of wood are all woodworking applications. Each one of these processes create large amounts of dusts that can harm worker health.

The planing, sawing, routing, milling, drilling and sanding of wood are all woodworking applications. Each one of these processes create large amounts of dusts that can harm worker health. The stone industry on the other hand, manufactures countertops, fireplaces or other stone-made fixtures for homes and offices.

The stone industry on the other hand, manufactures countertops, fireplaces or other stone-made fixtures for homes and offices.