Similar to grinding and deburring, sanding and finishing produces a number of dusts that are toxic when inhaled. The type of health risks depends on the type of material and the abrasive being used. Whether it is wood, metal or plastics, each material poses its own unique health problems.

Many of the metals used in aerospace manufacturing have been primed with chromate. Sanding metals with chromate primer exposes workers to the hexavalent chromium putting them at risk of developing cancer. Other health problems associated with the finishing of metals includes:

- Black lung

- Silicosis

- Tuberculosis

- Kidney disease

- Lung cancer

- Mild respiratory irritation

- Nausea and/or vomiting

- Headaches and dizziness

- Irritated eyes, nose and throat

- Chest pain

- Respiratory damage

- Difficulty breathing

- Excess fluid in the lungs

- Lead poisoning

- Nervous system damage

Carbon fiber as well as fiberglass and composite particles present yet more health risks for workers in the aerospace industry.

Made of strong carbon atoms, carbon fibers create fine dusts when sanded. If uncontrolled, these dusts can stick into skin and mucous membranes, causing irritation. Carbon fibers also have an epoxy coating that can lead to health problems with exposure. Conditions associated with sanding carbon fibers include:

- Lung damage

- Eye and upper respiratory tract irritation

- Dizziness

- Drowsiness

- Nausea and/ or vomiting

The dust and particles created from sanding fiberglass have the potential to penetrate the trachea and lungs and cause damage. They can also lead to asthma, allergies and even cancer. If not contained, fiberglass dust can wreak havoc on computers and other production equipment as well.

Air Filtration Solutions for Sanding & Finishing

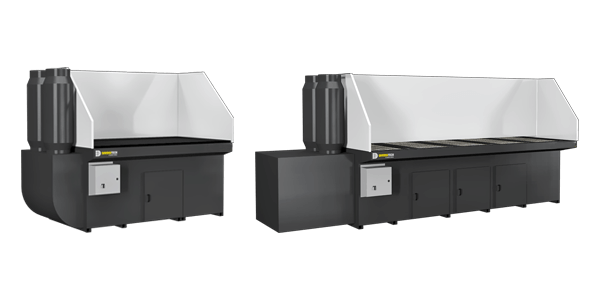

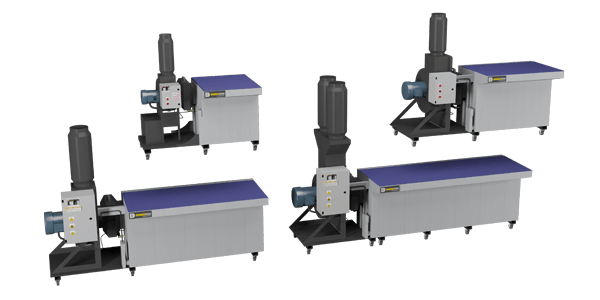

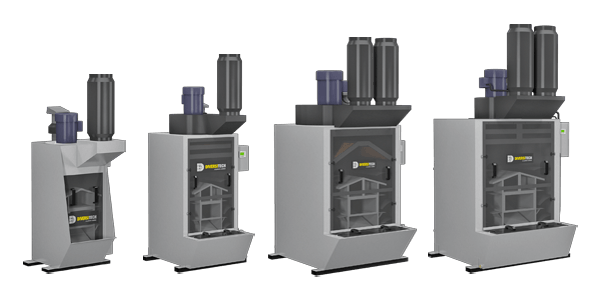

To avoid the buildup of toxic dust in the workplace, capture-at-source is the best option. Because most finishing work is done over table surfaces, a downdraft table is a popular solution. Diversitech offers a number downdraft tables, environmental booths and cartridge dust collectors for the safe and effective collection of finishing dusts. For the effective control of carbon fiber, fiberglass and composite particles, installing an air filtration system with a HEPA filter is required. For wide belt sanding applications commonly used in the aerospace industry, Diversitech offers wet dust collectors that can be attached directly to the machines.

grinding and deburring produces airborne metal, composite, rubber or fiberglass dust that can be highly toxic when inhaled.

grinding and deburring produces airborne metal, composite, rubber or fiberglass dust that can be highly toxic when inhaled. on other machines and electronics in the shop.

on other machines and electronics in the shop.