For more information about any of our products or services,

please provide the information below and one of our experts will call you back shortly.

For more information about any of our products or services,

please provide the information below and one of our experts will call you back shortly.

Answer: There are two main types of industrial ventilation systems that remove and control airborne contaminants. Source Capture and Ambient Air Cleaning are the two recommended methods to filter dust, smoke and fume from indoor work environments. A source capture system, also known as local exhaust, can be configured in two different ways. A ducted system will use “air intake” devices such as backdraft hoods, capture arms, booth enclosures, downdraft tables or other pickup hoods to convey particulate into a ductwork system, which terminates at a central dust, fume or mist collector. The second capture-at-source method is to use self-contained air filtration equipment, such as mobile fume extractors, portable downdraft tables, welding booths or wall mounted collectors to capture, filter and recirculate air without the need to install ductwork.

An ambient air cleaning system, also known as dilution or general ventilation, reduces the concentration level of particulate within a work area by exchanging the air several times per hour. Air cleaners need to be strategically positioned in a concentric arrangement to ensure adequate movement of air throughout the facility and to prevent dirty air from stagnating.

Whenever feasible, self-contained source capture systems are the most effective solution to extract and filter airborne contaminants due to these key advantages:

Ambient air cleaning systems are necessary whenever it’s not possible to implement a source capture system due to impediments such as overhead cranes, very large parts and facilities with no available floor space. Some of their advantages include:

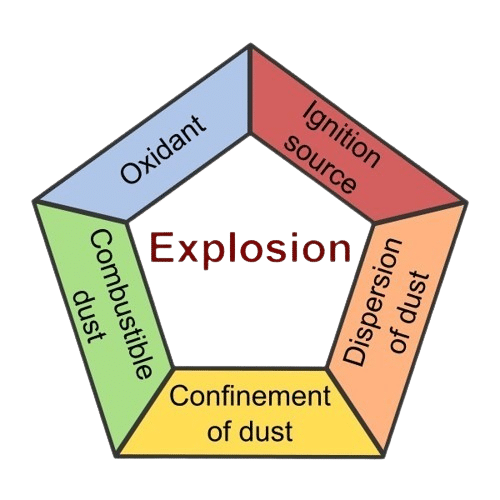

Because of the many NFPA codes (61, 484, 652, 654, 664) which ensure that dry dust collectors are safe to collect combustible dust, installing a new collector with fire protection systems can be prohibitively expensive. However, there is another cost effective solution which does not require the same type of options. A wet dust collector operates using water as the filter media instead of using a solid media filter. Once combustible dust comes into contact with cascading water, the dust is immediately rendered inert and cannot catch fire. There is no need for fire detection and suppression systems. The main difference between the systems is that wet dust collectors allow you to comply with NFPA guidelines while avoiding the expense of installing suppression and detection systems. Whenever combustible dust is present, a wet dust collector provides a cost effective and safe means to collect combustible particulate.

No products found.

No products found.

Our Team is Happy to assist! Contact Diversitech today to get started

Please provide the information requested below so we can provide you with a timely and customized solution for your specific needs.