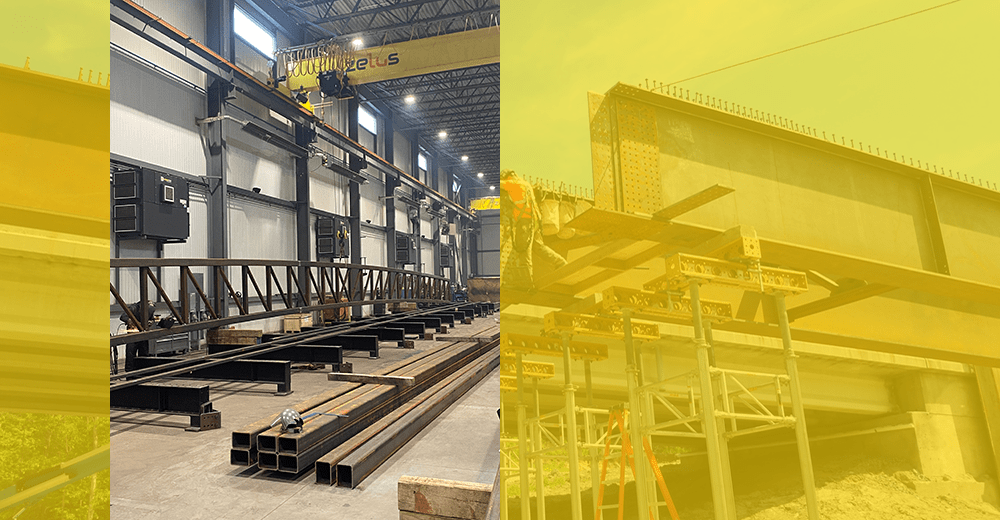

After meeting with the team at Iron Bridge Fabrication, Diversitech proposed a wide range of solutions to choose from – each with specific benefits. Doing so allowed Iron Bridge Fabrication to choose an option that was the best possible fit for their needs while staying within their budget.

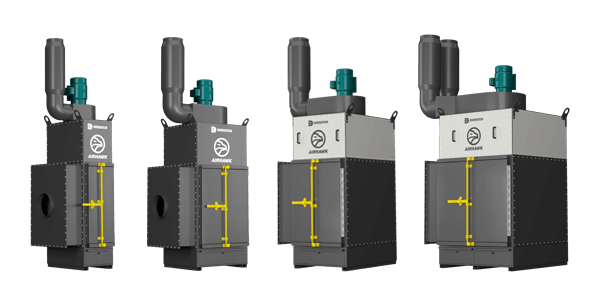

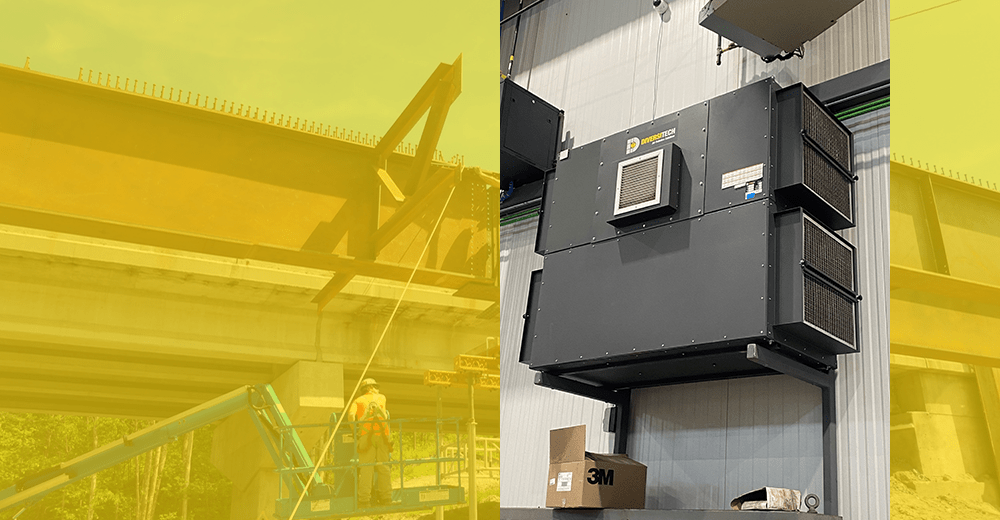

The chosen solution was nine (9) wall-mounted Filterhawk AM-Series Ambient Air Cleaners by Diversitech. Owing to its multi-stage filtration system, each Filterhawk AM Series Ambient Air Cleaner can capture a wide array of airborne contaminants ranging from coarse to very fine particulate, ensuring consistently clean air. These units create an airflow pattern that will effectively capture airborne smoke and dust generated from welding and grinding in Iron Bridge Fabrication’s manufacturing plant on a designed air exchange per-hour rate.

This solution offered the added benefit of requiring zero floor space and provided ideal ventilation throughout the entire plant, delivering a clean and safe work environment.