Effective Ventilation

The most efficient method to reduce exposure to hazardous fume generated during welding is through proper ventilation and source capture systems.

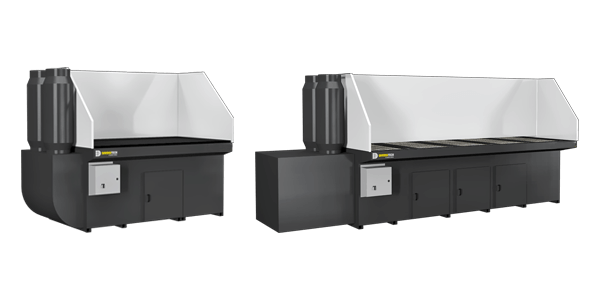

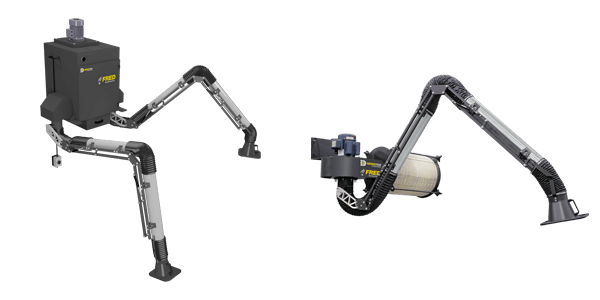

Capture-At-Source Solutions

Capture-at-source ventilation such as portable fume extractors and downdraft tables draw the fumes in and away from the operators’ breathing zones to protect workers. Indoor air remains uncontaminated.

If capture-at-source is not feasible, employers can opt for an ambient air cleaning solution. These systems are often used when welders work in wide open spaces or on large pieces. Used alongside capture-at-source, ambient air filtration helps create an even cleaner air facility.

But purchasing effective ventilation equipment is only part of the equation. A number of factors go into the proper use of air filtration equipment, including:

- The training of operators on safe use and capture zones

- The regular cleaning and servicing of filters

- The correct filter type for the materials being worked on

- Sufficient face velocity to draw in smoke and fumes created by the application

Failure to implement the above recommendations may result in an ineffective capture of airborne contaminants.

Ambient Air Filtration

When working on large assemblies or in open spaces, ambient air filtration systems support welding fume control by continuously cleaning the background air.

For best results, use both systems together.

Best Practices for Reducing Exposure

- Train operators on correct fume extraction equipment use

- Regularly clean and replace filters

- Match the filter type to the material (especially when welding galvanized steels)

- Maintain proper face velocity to draw in smoke effectively

Knowing how to prevent inhaling welding fumes starts with understanding your work environment and investing in the right safety systems.

Understanding Your Specific Application and Safety Requirements

The type of filtration equipment you choose depends on the materials worked on as well as your unique work situation. To properly asses your specific requirements, you’ll need to determine:

- Whether or not your welders work in a confined space with little ventilation

- The type of metals being welded

- If the work pieces are clean, painted, coated or covered with degreasing solvent

- Whether or not your filtration equipment is working properly

- If there are any prevalent air streams that you can leverage

- Whether or not your welders need to use a respirator