The Problem

In 2001, Diversitech installed a small fume extraction system which continues to do the job today. With this in mind, Tayco called on us to set up their new welding cell. Unfortunately, the welding fixtures were too large to accommodate a source capture system.

The Solution

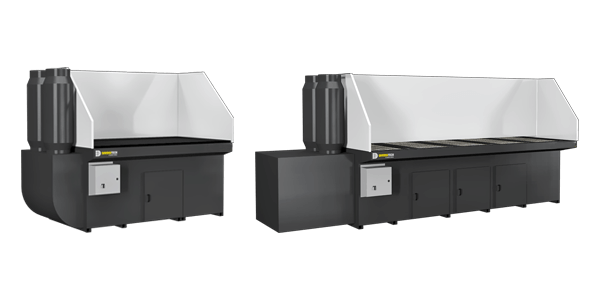

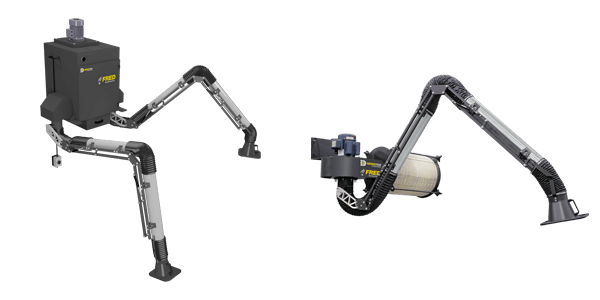

Instead, an overhead canopy hood system ducted to a FRED-02C was designed and installed. Operators were still required to wear masks however smoke from the process could now be captured by the hood before becoming a general nuisance. The FRED-02C cleans its own filter every time you turn it off. The patented ICS-360 Injection Self-cleaning System uses shop air to blow dust and smoke off of the cartridge filter and into a dust drawer for removal.