The Problem

As a manufacturer of skin care products, Northwest Cosmetic Labs needed an efficient and durable solution for capturing non-combustible, fine pigment dust at multiple workstations during the manufacturing process. Typical duty cycle is 20 hours daily. They required a solution that could duct to six (6) 6-inch capture arms.

The Solution

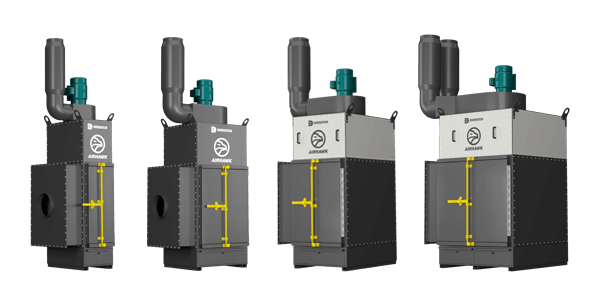

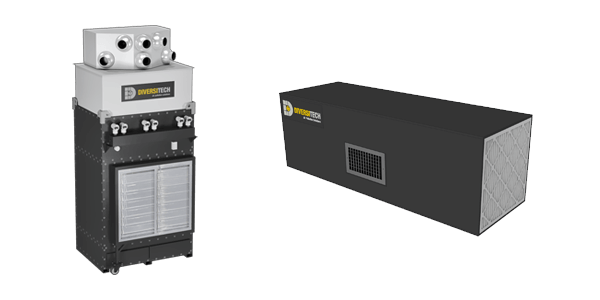

The 9-cartridge Filterhawk Cartridge Dust Collector from Diversitech was the chosen solution. To address the height restrictions within the facility, Diversitech was able to provide shorter, custom-fabricated legs and a smaller collection drum to support the unit.

Due it its powerful, centralized system, the Filterhawk easily supported multiple workstations without the need for individual units.

Diversitech also provided 6 additional 6.5’ extractor arms and wall-mounted brackets.

Conclusion

Northwestern Cosmetic Labs was pleased with Diversitech’s ability to deliver a customized and durable solution specific to their needs.