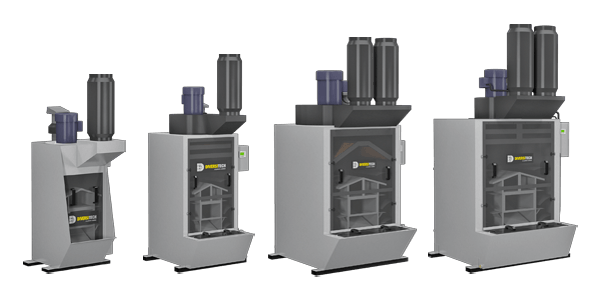

up to 8600 cfm

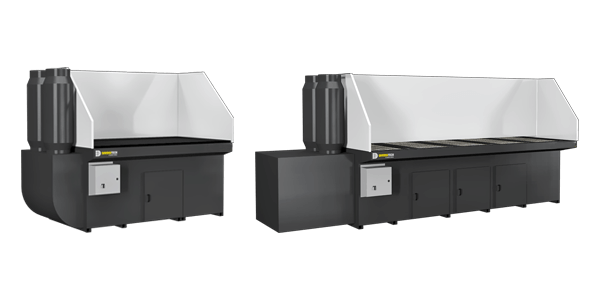

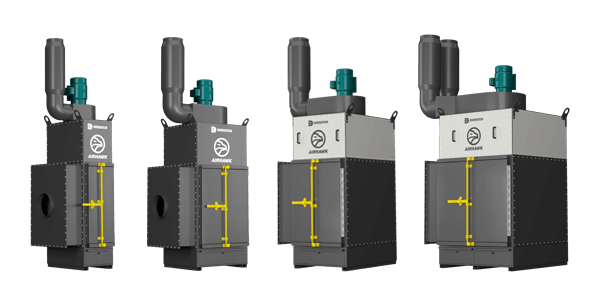

Installing high quality Downdraft Tables as part of your production process will provide workers with a safe environment to accomplish their work, while ensuring a high level of quality and performance to which you’ve grown accustomed.