Diversitech installed downdraft tables to capture the dust at the source and eliminate the problem. Air Canada recently published an article on this project in their internal newspaper The Leading Edge on August 8, 2005. A Health & Safety initiative to enhance the air quality in the Landing Gear Shop’s ‘Blend Room’ – the location used to grind, blend and polish landing gear and mechanical unit parts – has been completed, thanks to the determined efforts of shop employees.

Shop Health and Safety Representative Michel Courteau, had researched various suppliers to come up with equipment that would fit the bill. “Interestingly enough, the equipment that was most economical also turned out to be the best for our purposes,” Courteau told Leading Edge.

Following a detailed analysis of Courteau’s proposal, corporate approval to proceed with the $100,000 expenditure, and the selection of the equipment from Diversitech, Engineer Rami Hanna and Coop Engineer Nicolas Hoppenkamps took charge to ensure all installation details and specifications were carried out.

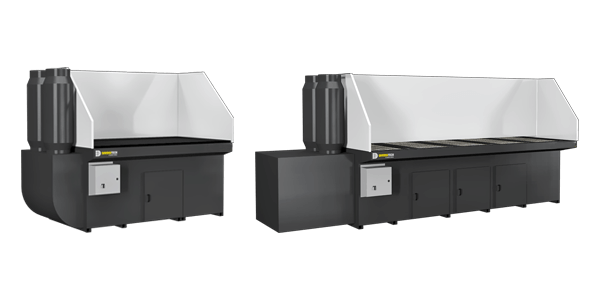

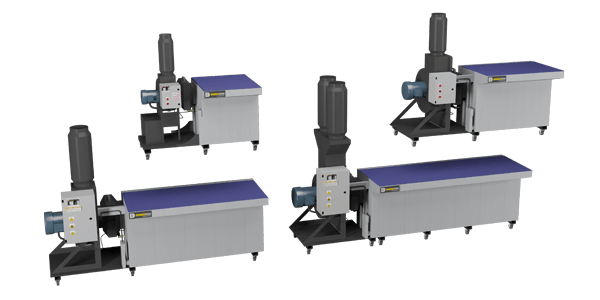

A stationary downdraft table and equipment with mobile rotating ‘arms’ that employees can move close to any work area in the Blend Room, sucks up both minute and larger particles in the atmosphere, and sends them through the filtration system located on an upper floor.

Renovations to install the unit began last May, with the equipment becoming functional on July 28. Final touch-ups to the unit were expected to be complete in the middle of August. “Michel, Rami and Nicolas really took charge of this project and they are to be congratulated.” said Team Leader Les McCartney.