What is Solder?

Solder is used by assembly workers in many industries to make electrical connections and to seal copper pipe during plumbing installations. It is typically available in a wire form made from various metals with a core of rosin flux on the inside. When heated with a soldering iron, the solder melts, flows, and solidifies to form a permanent connection.

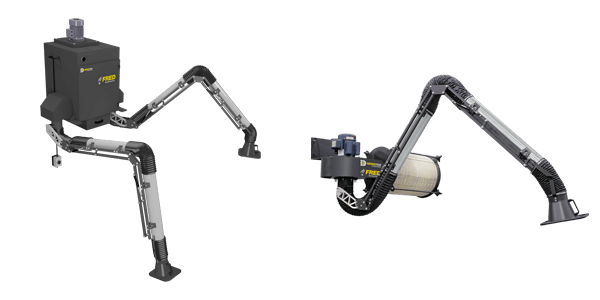

Soldering is accomplished by heating the two items to be connected with a soldering iron, and touching the heated points with the solder, which melts, flows, and solidifies to form a permanent connection. Flux helps to prevent oxidation during the soldering process but also produces toxic solder fumes when heated. Workers frequently ask, “Do I need a fume extractor for soldering?” The answer is yes—fume extraction systems are critical for maintaining clean air and reducing harmful exposure.