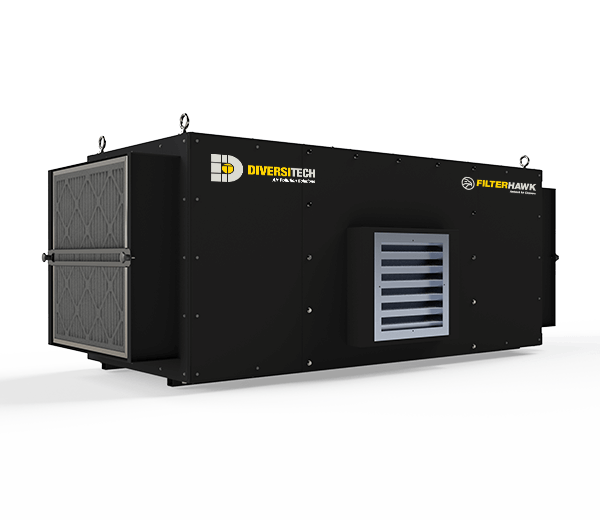

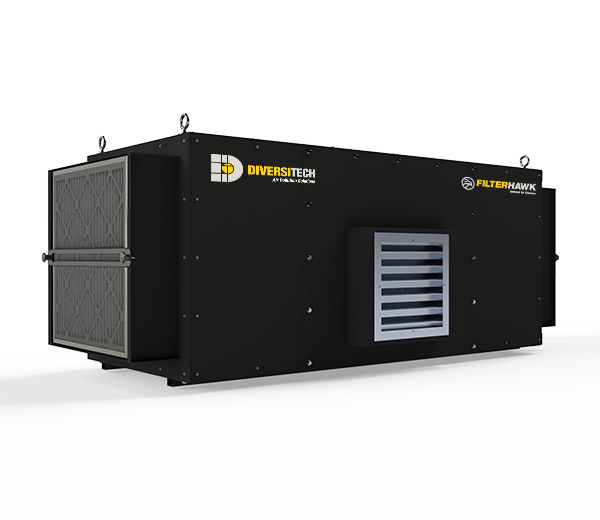

Technical Specifications

| Model (Product Number) |

Motor (H.P.) |

Air Flow (CFM) |

Volts/Phase/Hz |

Amps |

Net Weight1 |

Width1 |

Height1 |

Length1 |

Filter Quantity |

Pre-filter Type |

Filter Type |

| FH-A-3000 |

1.5 |

3000 |

120V/1/60Hz |

15.5 |

176.90 |

25″ |

25″ |

72″ |

6 |

MERV 7 (2x) |

MERV 8 Paper Pleated Filter (2x) / MERV 14 Bag Air Filter (2x) |

1 – Product weight and dimensions are based on base-models and may vary depending on selected product features. Please contact us for an accurate shipping quote.

Learn how to get the most out of your AM-Series 3000 Ambient Air Cleaner.

See our help topics and download the AM-Series 3000 Ambient Air Cleaner product guide and owner’s manual.