Top Weld Training and Staffing Agency is a leading weld training and placement company with two locations in Ontario and British Columbia, Canada. Their mission is to provide top-quality training and education to students aspiring to excel in the welding industry.

The Problem

When setting up their first Ontario-based facility, Top Weld faced a significant challenge in managing their fume extraction needs to ensure a safe, compliant, and efficient learning environment. Prioritizing a safe working environment for students and ensuring compliance with Canadian standards was critical.

The Solution

Diversitech offers a wide variety of extraction options for education facilities and different configurations such as welding booths, downdraft tables, and source capture extraction arms. After several discussions with Diversitech, Top Weld was introduced to the Fred Eco with 10’ extraction arm as the most suitable solution. Diversitech’s representative, Jared Simms, provided clear, practical guidance and performed an on-site visit to customize the solution for Top Weld’s specific requirements.

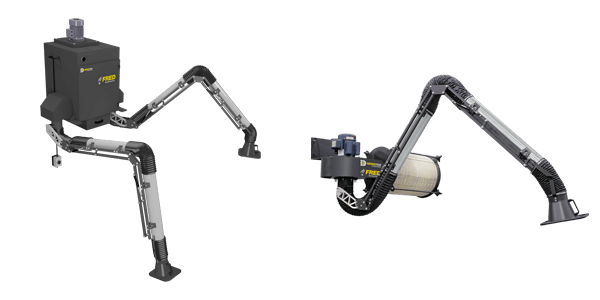

“Jared treats me as a colleague rather than a customer. He’s responsive to my emails, long after I’ve placed an order. I know that if I have an issue, I can call Jared and he will not only answer, but help me find a solution.”— Harpreet, Operations Manager, Top Weld. The FRED Eco is a self-contained workstation, providing each student with their own extraction arm, fan, filter, and on/off switch. The filtered air is recirculated within the facility using a MERV15 filter, eliminating the need for external exhaust. This design retains indoor heat during winter months and prevents negative pressure within the space.

The 10’ long x 6” diameter XA4 capture arm effectively captures welding smoke at the source, protecting the welder’s respiratory zone and limiting smoke migration and inhalation.

Results

The FRED Eco solution was first implemented in Top Weld’s Ontario facility, where it delivered such outstanding performance that the company expanded its use to their British Columbia location. Today, Top Weld operates 37 FRED Eco units across both locations, ensuring a clean and safe working environment.

The results have been outstanding:

- Over 700 students successfully trained in a safe, compliant environment.

- Zero student injuries related to air quality.

- Consistently high air quality and efficient fume extraction.

- Minimal maintenance and high durability of the FRED Eco units.