The WV Sludge Vacuum quickly and easily cleans dust, chips and swarf out of wet dust collectors and other equipment. Ideal for use on machines with sumps, parts washers or any storage container with contaminated liquids, the WV Sludge-Vac reduces manual maintenance requirements.

The WV Sludge Vacuum’s powerful, compressed air-powered, reversible drum vac can fill or empty a drum in less than two minutes. Set the directional valve on “fill”, and the WV quickly vacuums up any liquid and solids from your wet dust collector. Set to “empty”, and the pump releases filtered water minus the solids for reuse back into the wet collector. All the dust, chips and other solids remain collected inside the reusable 5 micron filter bag for easy and safe disposal.

| Model | Air Consumption | Water Flow Rate | Net Weight (lbs.) | Noise (dB) | ||

|---|---|---|---|---|---|---|

| SCFM | SLPM | GPM | LPM | |||

| WV-55-030W1 | 19 | 538 | 30 | 114 | 20.41 | 86 |

| Model | Product Dimensions (in.) | ||

|---|---|---|---|

| Width | Heigth | Length | |

| WV-55-030W1 | 24 | 48 | 24 |

1 – Product dimensions are based on base-models and may vary depending on selected product features. Please contact us for an accurate shipping quote.

Learn how to get the most out of your WV Sludge Vacuum.

See our help topics below, and download the WV Sludge Vacuum product guide and owner’s manual.

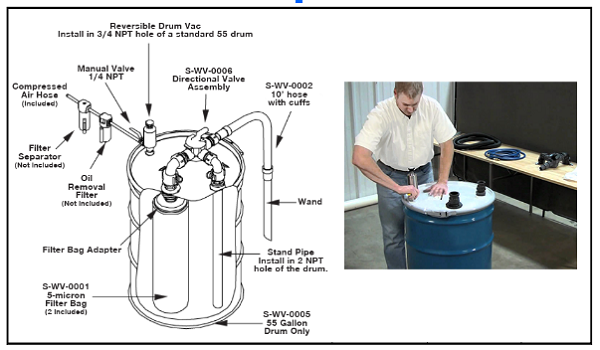

Please refer to the image below:

To replace the filter in your WV Sludge Vaccum, do the following:

Routine cleanings of your WV Sludge Vacuum will ensure optimal performance of your unit. To properly clean your WV Sludge Vacuum, do the following:

If the Sludge Vacuum becomes clogged, disassemble it for cleaning:

No data available.

40 gallon water capacity, stainless-steel wet dust collector with silencer.

80 gallon water capacity, stainless-steel wet dust collector with silencer.

80 gallon water capacity, stainless-steel wet dust collector with silencer.

Please provide the information requested below so we can provide you with a timely and customized solution for your specific needs.