The Problem

In early-2020, Magellan Aerospace moved into their new manufacturing plant and required a new dust and smoke extraction system to ensure their facility was compliant and free of harmful airborne toxins which could be inhaled by their employees. As part of their manufacturing process, deburring is used to finish steel components, generating fine metal particles.

Submicron dusts (measuring 0.5 micron and smaller) are particularly dangerous if inhaled, as they can easily settle in the lungs. Health risks from steel deburring dust may include:

- Pneumoconiosis

- Lead poisoning

- Nausea and dizziness

- Irritated eyes, nose and throat

The Solution

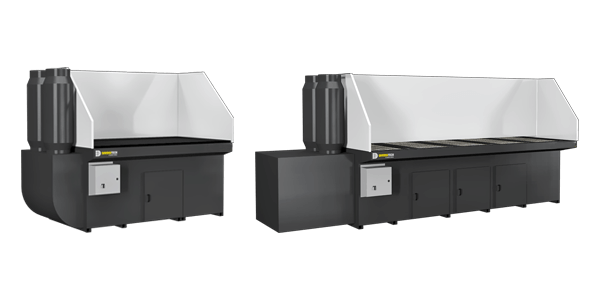

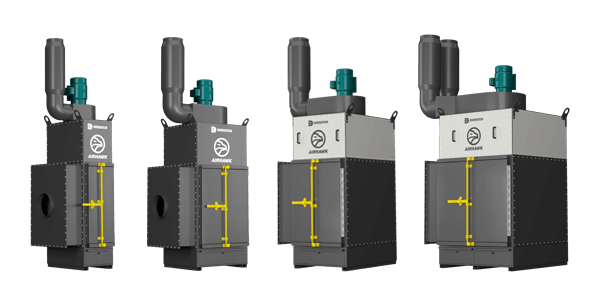

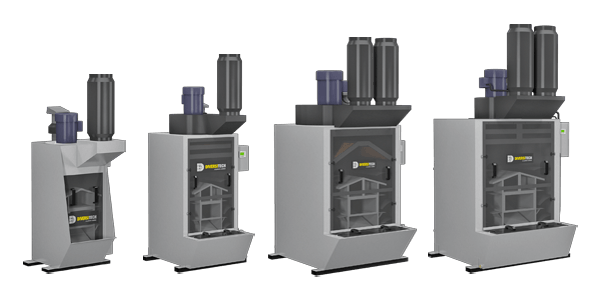

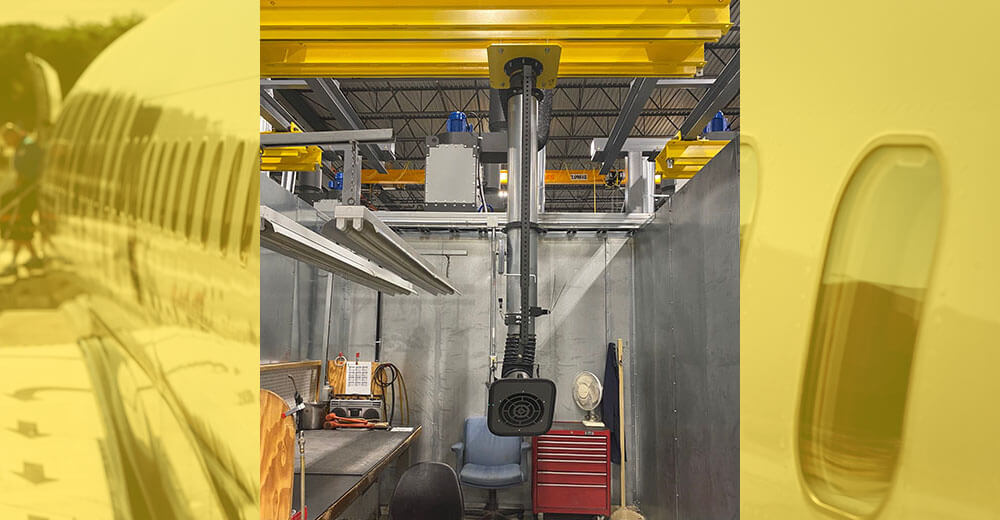

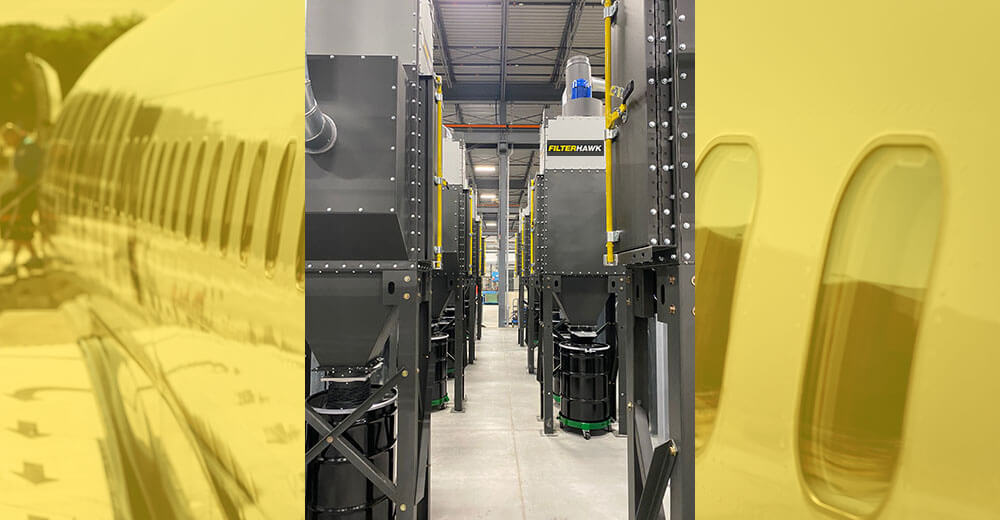

Magellan Aerospace required a system that would capture harmful dust at-source, while allowing workers flexibility to work in virtually any position. Diversitech provided an engineered solution featuring twelve (12) suspended retractable capture arms, each housed within its own booth enclosure and ducted to its own dedicated Filterhawk FH-02 Cartridge Dust Collector.

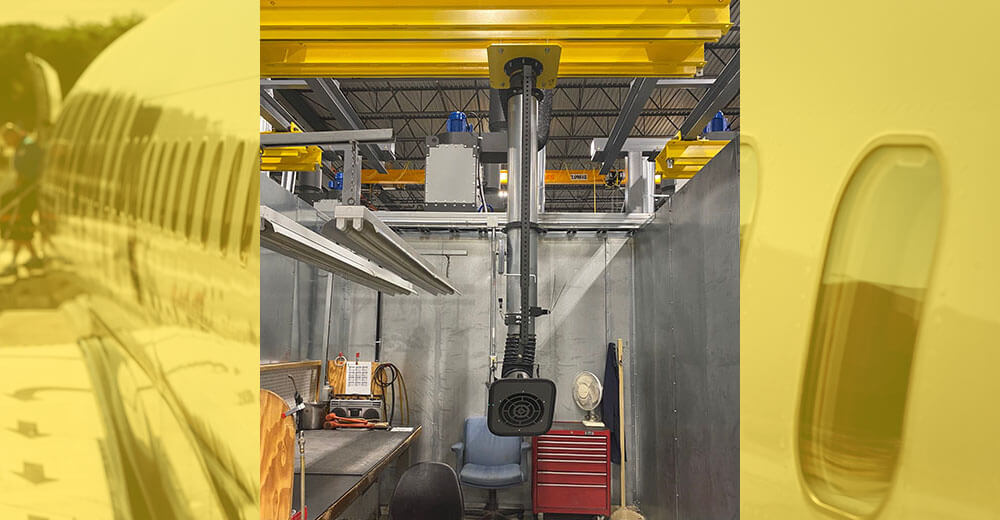

A booth enclosure with a retractable extraction arm.

The arm is mounted to an overhead sliding beam.

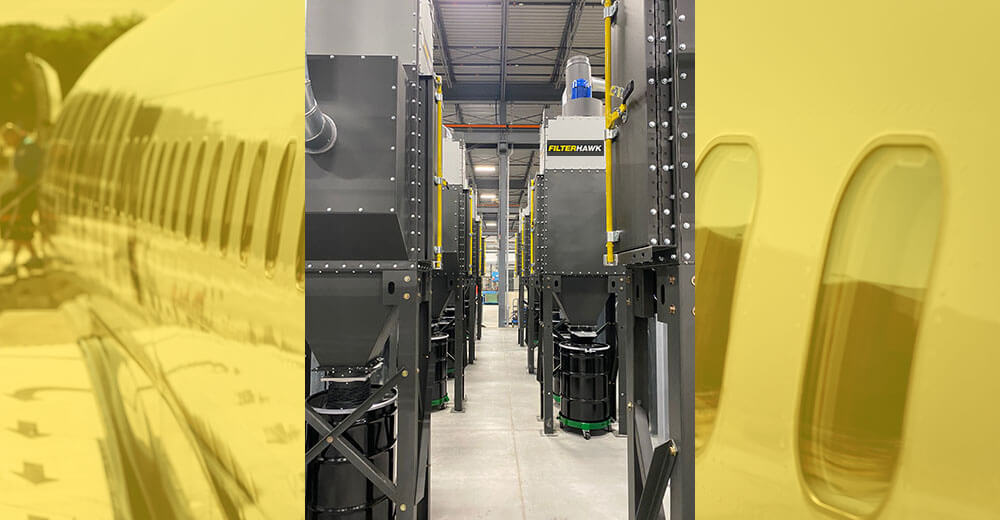

Twelve (12) Filterhawk Cartridge Dust Collectors.

Previous

Next