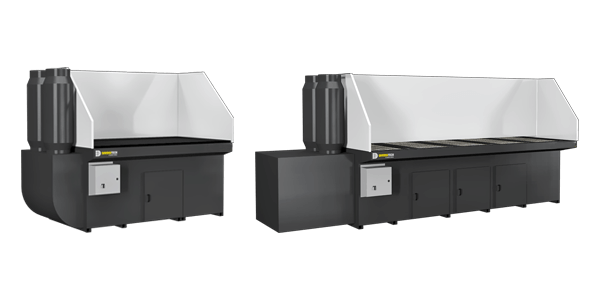

Grinding and deburring are common industrial processes, but they release fine dust particles that can pose serious risks. Whether it is an angle grinder, die grinder or an automated grinding machine, dust and particles will pollute your workplace unless they are captured and filtered at the source.

The best way to protect workers is through source capture for grinding dust. Removing dust before it reaches the breathing zone prevents long-term exposure and keeps air safe. Depending on the nature of the work application, grinding and deburring can create airborne metal, composite, rubber or fiberglass dust that is particularly dangerous to inhale.

Health Dangers of Grinding Dust

Metal dust inhalation can have life-threatening consequences. When workers breathe in grinding dust, the particles enter the lungs and may cause:

- Pneumoconiosis (also known as “dusty lung”)

- Scar tissue buildup that limits lung functioning

- Increased risk of chronic respiratory illness and other lung diseases

Dust hazards don’t stop at the lungs. Some particles dissolve into the bloodstream and travel to the liver, kidneys, or even the brain. This can lead to broader organ damage and long-term health complications.

Health Dangers of Grinding Dust

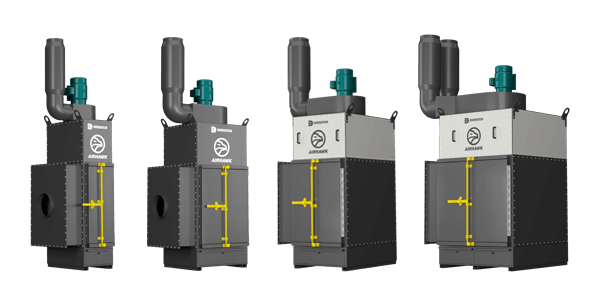

Creating a work environment that gives workers the ability to capture and filter grinding and deburring dust at the source is the key to safe prevention. The degree of risk to workers is determined by factors such as the length of exposure, the type of material being worked with, the type of protection and the effectiveness of that protection.

Dust Hazards and Worker Protection Equipment

Creating a safe work environment requires effective dust control measures. The risk of lung disease depends on:

- Length of exposure to dust

- Type of material being worked on

- Effectiveness of protection equipment

- Quality of dust removal systems

By implementing proper control measures for dust in the workplace, employers can drastically reduce exposure and keep workers healthy.