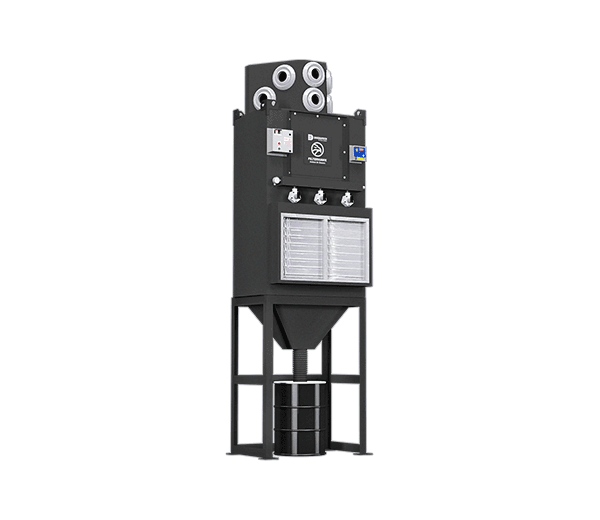

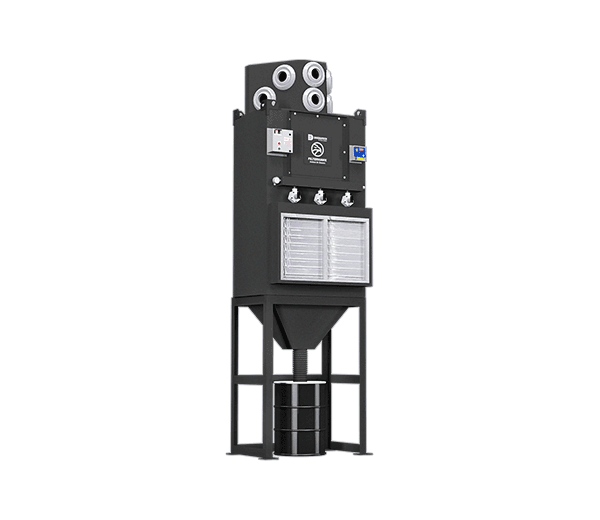

- Motor: 7.5 HP / 230V/3/60hz

- 6 Cartridge Filters

- Filter Type: MERV 11 (x6)

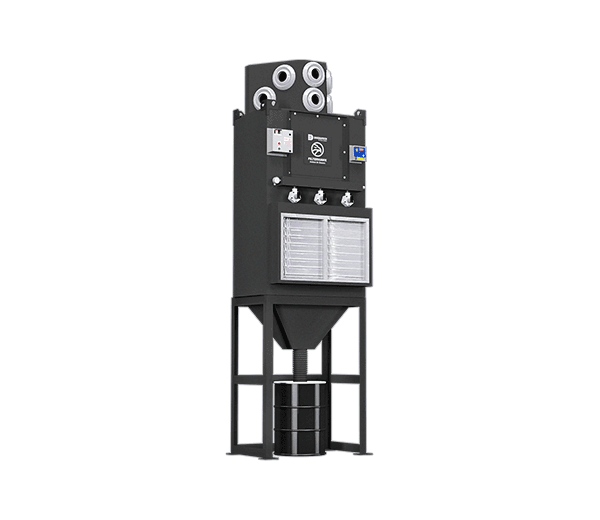

- Product Number: FHA-06S-075T2

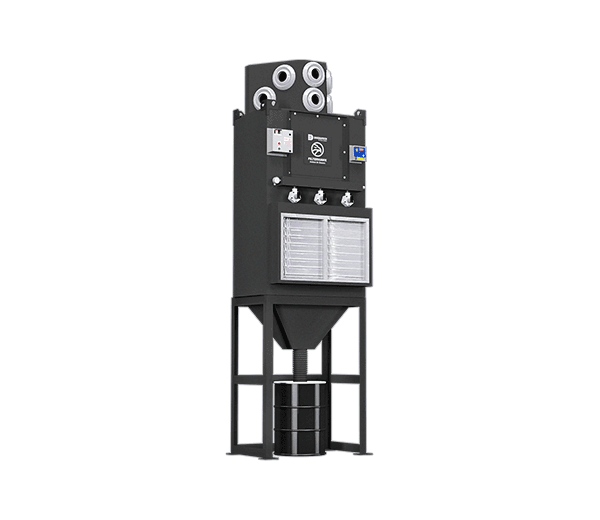

Diversitech’s Filterhawk Ambient Tower Collector captures and filters dust, smoke and fumes from your industrial work space. Using high-efficiency NanoFiber filters, the Filterhawk Ambient Tower Collector draws in and cleans contaminated air before returning it back into the facility. Climate controlled air remains indoors, keeping energy costs to a minimum.

The collector’s self-cleaning filter system can be fitted with a hopper and dust collection drum, making it one of the lowest maintenance ambient air cleaners in the industry. Equipped with 6 powerful dust collecting cartridges, the Filterhawk Ambient Tower Collector can clean up to 6000 cubic feet per minute (CFM). Available in a wall-mount or ceiling-mount configuration, the Filterhawk Ambient Tower Collector is perfect for any application where capture-at-source isn’t practical.

Ideal applications include: welding smoke & fumes; grinding, buffing & polishing dust; grinding composites & plastics; handling of dry powders; packaging, blending or weighing; wood sawing sanding or finishing; oil mist & smoke from machining.

Diversitech’s Filterhawk Ambient Tower Collector captures and filters dust, smoke and fumes from your industrial work space. Using high-efficiency NanoFiber filters, the Filterhawk Ambient Tower Collector draws in and cleans contaminated air before returning it back into the facility. Climate controlled air remains indoors, keeping energy costs to a minimum.

The collector’s self-cleaning filter system can be fitted with a hopper and dust collection drum, making it one of the lowest maintenance ambient air cleaners in the industry. Equipped with 6 powerful dust collecting cartridges, the Filterhawk Ambient Tower Collector can clean up to 6000 cubic feet per minute (CFM). Available in a wall-mount or ceiling-mount configuration, the Filterhawk Ambient Tower Collector is perfect for any application where capture-at-source isn’t practical.

Ideal applications include: welding smoke & fumes; grinding, buffing & polishing dust; grinding composites & plastics; handling of dry powders; packaging, blending or weighing; wood sawing sanding or finishing; oil mist & smoke from machining.

The Filterhawk Ambient Tower Collector standard base model comes equipped with six (6) MERV 15 filters and a 208V, 7.5 HP motor, but the following options are also available upon request:

| Model (Product Number) | Motor (H.P.) | Air Flow (CFM) | Volts/Phase/Hz | Amps | Net Weight1 | Width1 | Height1 | Length1 | Filter Quantity | Filter Area (Sq. Ft) | Filter Type |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FHA-06N-075T8 | 7.5 | 4000 | 208V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 15 (x6) |

| FHA-06N-075T2 | 7.5 | 4000 | 230V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 15 (x6) |

| FHA-06S-075T2 | 7.5 | 4000 | 230V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 11 (x6) |

| FHA-06N-075T4 | 7.5 | 4000 | 460V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 15 (x6) |

| FHA-06S-075T4 | 7.5 | 4000 | 460V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 11 (x6) |

| FHA-06N-075T5 | 7.5 | 4000 | 575V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 15 (x6) |

| FHA-06S-075T5 | 7.5 | 4000 | 575V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 11 (x6) |

| FHA-06N-100T8 | 10 | 5000 | 208V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 15 (x6) |

| FHA-06S-100T8 | 10 | 5000 | 208V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 11 (x6) |

| FHA-06N-100T2 | 10 | 5000 | 230V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 15 (x6) |

| FHA-06S-100T2 | 10 | 5000 | 230V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 11 (x6) |

| FHA-06N-100T4 | 10 | 5000 | 460V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 15 (x6) |

| FHA-06S-100T4 | 10 | 5000 | 460V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 11 (x6) |

| FHA-06N-100T5 | 10 | 5000 | 575V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 15 (x6) |

| FHA-06S-100T5 | 10 | 5000 | 575V/3/60hz | N/A | N/A | N/A | N/A | N/A | 6 | 1890 | MERV 11 (x6) |

1 – Product weight and dimensions are based on base-models and may vary depending on selected product features. Please contact us for an accurate shipping quote.

Learn how to get the most out of your Filterhawk Ambient Tower Collector.

See our help topics and download the Filterhawk Ambient Tower Collector product guide and owner’s manual.

All of the mechanical installation must be performed by a qualified installer and in accordance with local, state, and national codes/regulations/laws (if any).

All electrical installations must be performed by a qualified electrician and in accordance with local, state, and national codes/regulations/laws (if any).

The compressed air installation should be performed by a qualified installer and in accordance with local, state, and national codes/regulations/laws (if any).

For optimal performance, routine maintenance is highly recommended. Do the following:

Check and empty dust drawer and hopper contents periodically.

NOTE: The frequency depends on the number of operating shifts and plant conditions.

The spark baffles are located underneath the grating and should be periodically cleaned with mild soap and water.

Periodically open the drain valve attached below the tank to drain the liquid build-up in the air tank.

For optimal performance, clean filters are necessary. To replace your filters, do the following:

Periodically inspect and clean metal mesh filters as any buildup of material in the filters can lead to fire. Do the following:

Cartridge Filters will need to be replaced periodically. The frequency varies from a few weeks to a few years, depending on factors such as density of fumes/dust, particle size, humidity of air, oil or grease contents of matter. Do the following:

No data available.

Get an in-depth look at Filterhawk Ambient Tower Collector and explore its key features in action. This video showcases how it works, its standout benefits, and why it’s the perfect choice for you. Watch now and experience the innovation firsthand.

A four-cartridge solution featuring an innovative, modular design that effectively eliminates dust, smoke and other airborne contaminates from your work environment.

A six-cartridge solution featuring an innovative, modular design that effectively eliminates dust, smoke and other airborne contaminates from your work environment.

Diversitech’s Filterhawk AM-Series 3000 Ambient Air Cleaners are packaged air filtration systems that are designed to eliminate dust, smoke and other airborne pollutants with a high efficiency filtration system.

Diversitech’s Filterhawk AM-Series 4500 Ambient Air Cleaners are packaged air filtration systems that are designed to eliminate dust, smoke and other airborne pollutants with a high efficiency filtration system.

Please provide the information requested below so we can provide you with a timely and customized solution for your specific needs.