The Problem

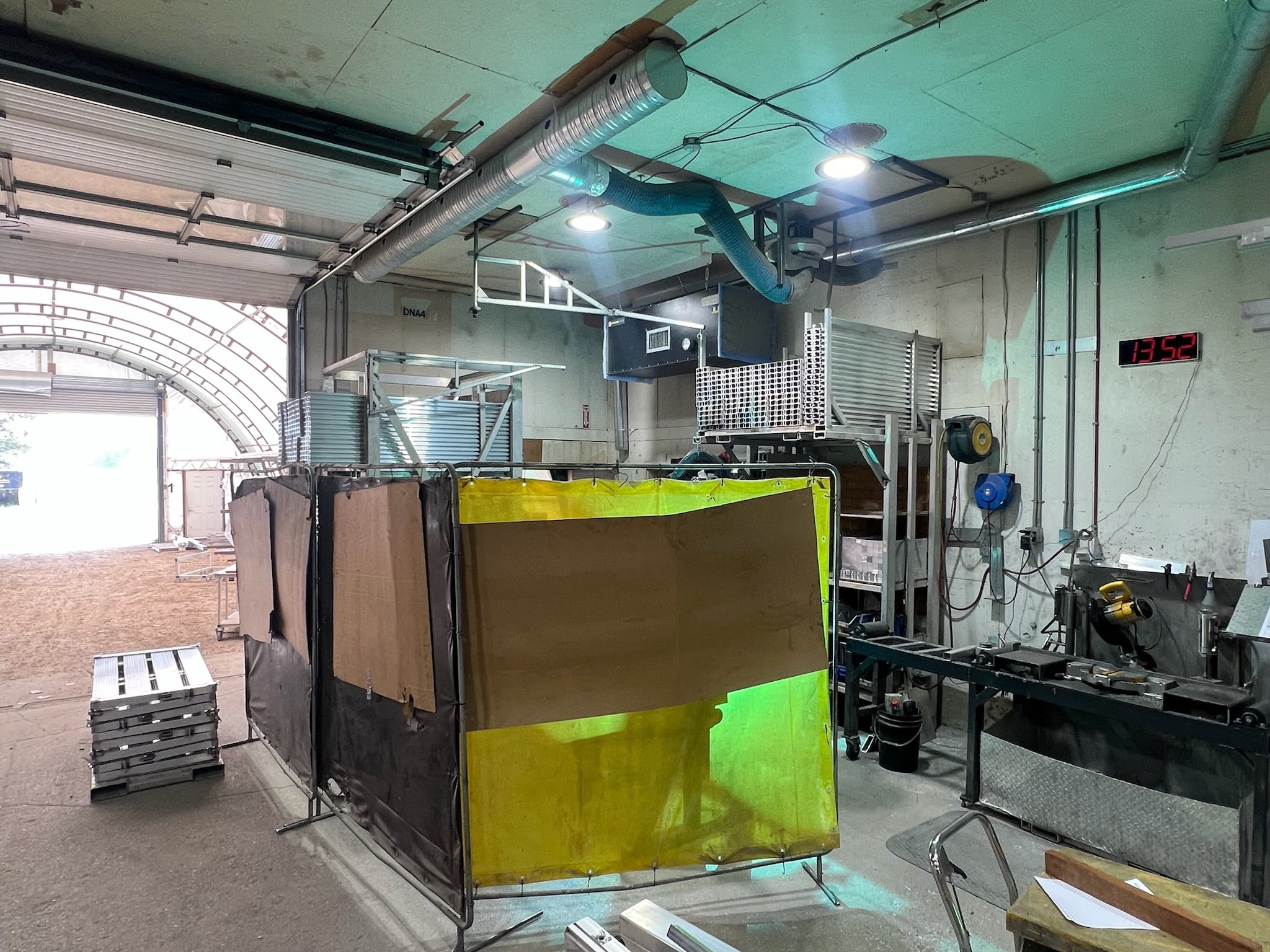

Diemo had several areas of concern due to welding smoke and metal dust generated by applications involving steel, stainless steel, and aluminum. These airborne contaminants posed significant health hazards on the overall air quality in Diemo’s warehouse.

The Solution

After the on-site assessment, the Diversitech team developed a comprehensive plan that addressed each work zone’s unique needs. Whether the area was large or small and the duty cycle light or heavy, Diversitech tailored each recommendation to the process, required filtration efficiency, and budget.

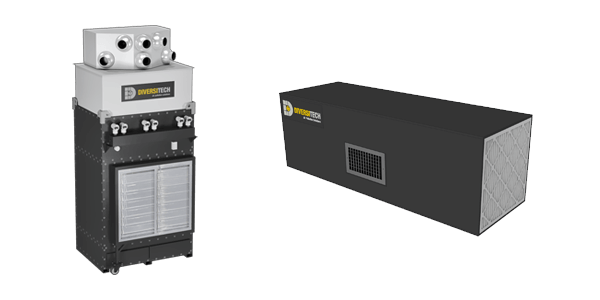

For the aluminum and stainless-steel areas, AM Series units were deployed to provide filtration exactly where needed. As for the steel welding area, multiple StormTower Pro systems were installed in the heavy-duty carbon-steel welding cell to deliver high-capacity airflow, modular scalability, and VFD-driven performance.

“Our previous system was outdated and ineffective, so we researched and implemented a solution that truly works. Ultimately, we wanted consistent air quality across the facility – so everyone, from welders on the floor to office staff, breathes the same clean air.”

– Allan Friesen, Director, Strategic Initiatives & Procurement, Diemo