Machining

Does Your Workplace Use Machining Applications?

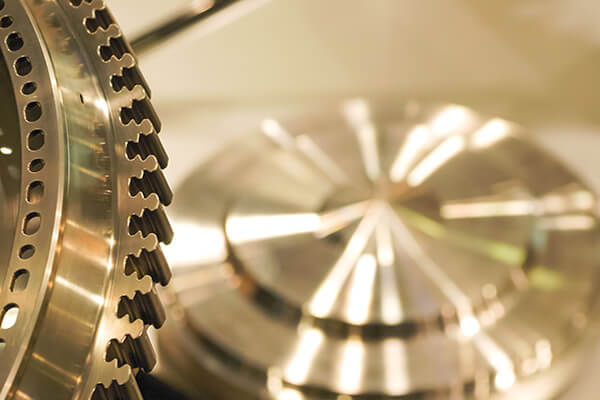

Machine shops rely on cutting fluids for their CNC machines to cool and lubricate heated parts during machining processes. The oils and synthetic coolants are sprayed near a cutting tool that generates an aerosol of oil mist and sometimes sub-micron smoke particles. The airborne mist can settle on surfaces throughout a production facility and contaminate the indoor air quality.

The machining industry has been pursuing increased productivity and quality through faster machine speeds and tighter tolerances, leading to the use of high-pressure coolant which can generate hazardous fine airborne droplets that need to be controlled. Whether manufacturers are turning, drilling, milling, grinding, heat-treating or die casting, airborne mist and smoke can become a serious health and safety risk in the workplace.

Health Effects of Oil Mist in the Workplace

Airborne oil mist presents a major problem for the machining industry as the mist-laden air can be inhaled by machine operators causing health complications and will settle on surfaces all over the machine shop. Once the mist accumulates on the shop floor, surfaces become a slip-and-fall hazard and oil mist can get into sensitive electronic equipment damaging machinery. The coolants can also generate toxic VOC fumes and typically produce a foul odor in the air. Some cutting fluids also contain chemicals that can irritate the respiratory tract and lead to a number of health issues.

The following health and safety hazards are associated with airborne oil mist:

- Asthma

- Pneumonitis

- Bronchitis

- Cancer

- Nervous System damage

Metalworking Fluid Regulations

The following regulatory agencies in the United States have established enforceable standards to control oil mist in the workplace:

- OSHA (Occupational Safety and Health Administration) has put in place a PEL (Permissible Exposure Limits) to regulate the amount of oil mist allowable over an 8-hour TWA (Timeweighted average) Period which is 5 mg/m3.

- ACGIH (American Conference of Governmental Industrial Hygienists) has also recommended the same PEL level for mineral oils.

- NIOSH (National Institute for Occupational Safety and Health) has a much smaller PEL, recommending machine shops not to except 0.4mg/m3 for a 10-hour TWA.

Solutions

With Diversitech’s D-Mister oil mist collector, machining centers can be connected directly to collectors designed to capture and ventilate machining enclosures without the risk of oil mist escaping and contaminating your facility. Once the cutting fluid is collected in the mist eliminator through a multi-stage filter system, excess coolant drains from the filters and can be collected in a container for reuse to save cost and waste.

For applications involving mist and smoke, D-Misters can be set up with HEPA after filters to ensure that the smoke is filtered and removed before recirculating clean air. The units are modular in size and are designed to ventilate individual or multiple CNC machines.

Contact us today for more about how we can help.